With the growth of the global supply chain, warehouses are constantly under pressure for better, faster, and more efficient performance. As this pressure grows, the role of lean warehousing becomes increasingly relevant.

Click Here: Have a Leaner Warehouse With This Advanced and Affordable WMS

However, since lean is relatively new to the warehousing industry, many of us may not be acquainted with it yet. So, here’s what it is and why your warehouse needs to be lean, too.

What is Lean?

The lean way of thinking was developed by Toyota for automotive manufacturing. It aims to eliminate any activity or procedure that uses resources but does not add value in return.

It is a systematic method to minimize wastage (Muda) without compromising productivity. It also aims to eliminate wastage created by overburden (“Muri”) and inconsistency in workload (“Mura”).

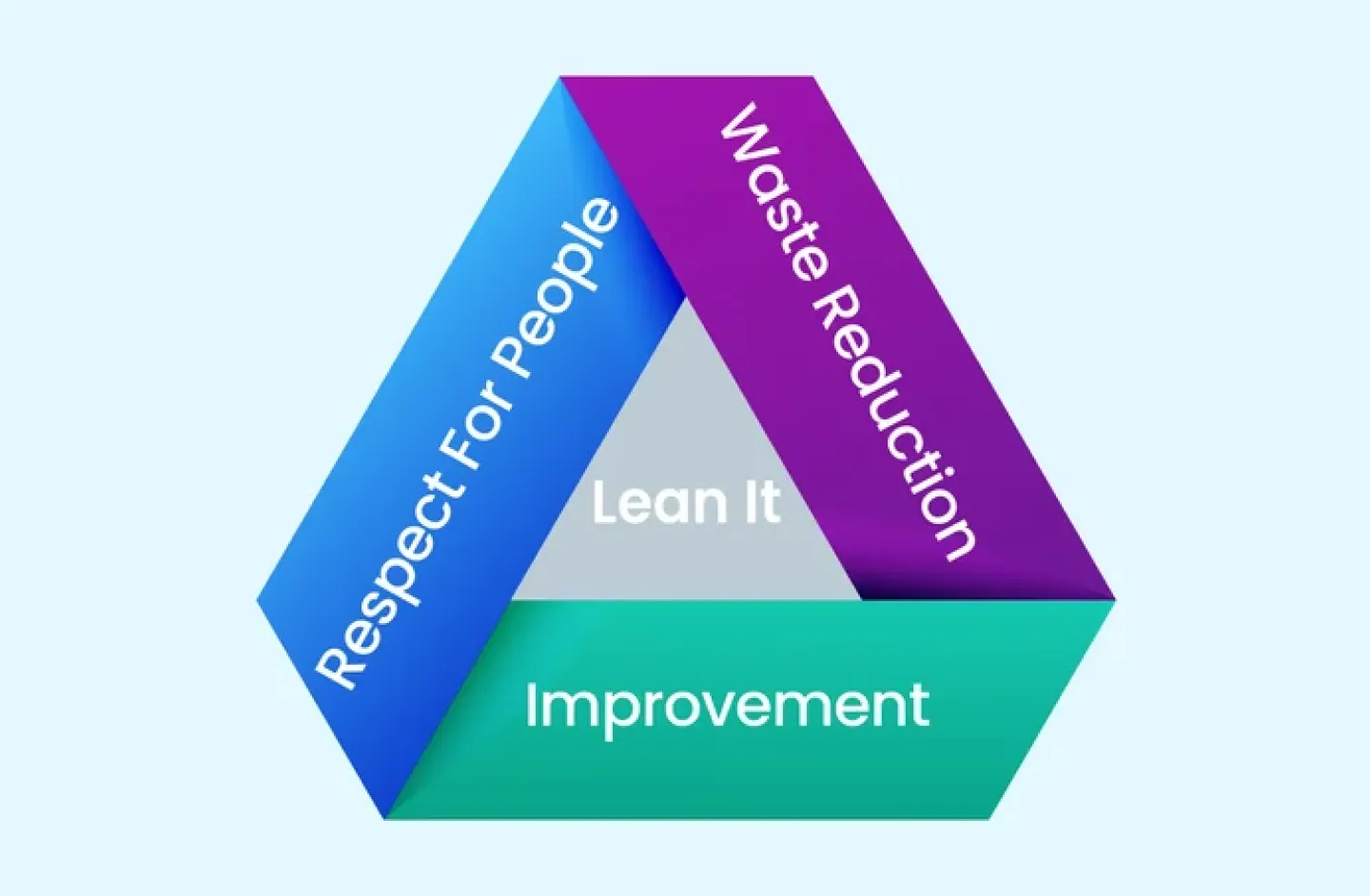

Here is the basic principle that Lean follows:

Though the concept was originally created to be implemented only in manufacturing, it can be applied to other industries, including warehousing, because of its simple framework.

What is Lean Warehousing?

Modern-day warehouses are not restricted to storage. Since their operations include processes such as receiving, put-away, picking & packing, dispatch, and shipping, the lean methodology is also being applied to warehousing.

In the context of lean warehousing, the idea is to eliminate processes and activities that are absorbing resources but not creating any additional value. This is done by applying the 5S system of lean, which are Sort, Straighten, Shine, Standardize, and Sustain, to the warehouse’s processes and procedures.

Why Lean for Warehouse Management?

The need for the lean warehousing methodology can be best understood in the context of the challenges that warehouse managers face every day. Here are a few of the major ones:

- Reducing operational costs

- Coping with the pressure of shorter lead times

- Increasing the number of perfect orders

- Meeting the target of same-day/next-day deliveries

- High attrition rates and rising cost of labor

- Managing multiple delivery channels

- Managing an increasing number of SKUs

- Shortage of space

- Seasonal/fluctuating demands

These are only a few challenges that crop up in the face of the rising prospects of commerce. Here is where Lean can help. While on a broad level, lean will lead to better efficiency, reduced errors, and maximum asset optimization, here are a few specific goals that lean can help you achieve:

- Standardizing workflow, resulting in shorter order processing time

- Optimizing asset utilization by finding the right place for the right inventory/equipment

- Eliminating inefficiency in material handling, thus reducing labor and transportation costs

- Stocking as per demand, thus enabling easy tackling of seasonal demand

- Cutting time wastage, thus helping you achieve a higher rate of perfect orders and same-day/next-day deliveries

- Standardized processes that make it easy to manage and assess multiple SKUs

- Better human resource management leads to lower attrition rates

- Making way for new ideas and innovation, thus bringing constant improvement

A media release from McKinsey & Company projects that, depending upon the nature of the business:

Applying lean warehousing management can save up to 20%-50% costs.

Here are a few examples where lean warehousing aims to remove wastage in the warehouse:

- Internal transportation – driving an empty forklift when it could be loaded

- Defects – adjustments, mis-picks, rework

- Inventory – congested inbound and outbound areas, poor visibility of stock, storing obsolete stock

- Material storage and handling – areas not being fully utilized, storing the wrong stock at the wrong place, using inefficient and wasteful methods for material handling

- Movement (of people) – interruption in movement of warehouse staff because of staging stock before putaway

- Waiting time/delays – bottlenecks at pick locations, delays in shipping approvals

- Overproduction – holding more stock than required

- Over-processing – performing unnecessary activities like labeling and checking when not needed

- Ignoring employee creativity – not welcoming ideas and innovation, thus hampering growth and lowering morale

- Overengineering – using a complicated process/equipment where a simpler one can prove to be efficient

Applying Lean in the Warehouse

Lean warehousing works on the 5S system, which was originally a lean manufacturing process. It is a comprehensive method that systematizes, cleans, and organizes as well as standardizes the warehouse.

Here are the 5Ss of lean:

1. The First S – Seiri – Sort

Sorting out the warehouse is the first step. You need to separate the things that you need from the ones that you don’t.

How to Sort:

- Removing unnecessary things, such as damaged/outdated stock, surplus stock, broken pallets, defective warehouse equipment, etc., is a good way to solve the problem of space shortage.

- You can also consider reducing or ending unnecessary movement, for example, creating a cross aisle within the picking area to effectively reduce operators’ travel time.

- Replacing manual paper picking with technology such as scanners or voice picking, etc., can extensively remove wasteful activities.

- Mark the items that need to be disposed of and keep them in a separate place until the approval for final disposal is obtained.

2. The Second S – Seiton – Straighten

Sorting should be followed by straightening out. Decide on a way of organizing things to increase efficiency.

How to Straighten:

- Place more frequently used items in more easily accessible places.

- Add inventory tags and labels to stock and bins to save time when locating items.

- Put warehouse signs and instructions to add to the scheme of organization and keep the warehouse clerks guided, which reduces fetching time.

- Install floor and aisle markers to improve pedestrian traffic and prevent confusion.

- Keep empty pallets and packaging at a point that can be accessed easily whenever needed.

- Install reminder equipment parking areas for staff to charge the equipment as shifts end.

3. The Third S – Seiso – Shine

This S stands for shining or cleaning the workplace after the work is done. A schedule must be maintained for this.

How to Shine:

- Get all the work areas cleaned at the end of shifts. This allows any defects or damages to be reported almost immediately.

- Place garbage cans in front of each aisle to ensure that waste packaging paper, broken pallets, etc., are not littered around.

- Also, keep basic janitorial supplies and services at the ready. Keep spill kits handy in case of accidental spillage or littering in the aisles.

According to a report from the US Bureau of Labor Statistics,

During the year 2015, slips and trips were the second biggest cause of fatal accidents at the workplace.

4. The Fourth S – Seiketsu – Standardize

Uniformity can only be brought through standardization. Creating standards for all work areas in the warehouse is essential. This is what the fourth S commands.

How to Standardize:

- Walk through each process with the staff and document warehouse operation best practices and procedures.

- Make standardized processes and procedures accessible and visible for staff to follow.

- Make the display of these procedures easy to understand and photographic.

- Use posters and charts, which are received rather well, with more to see and less to read.

- Implement training manuals and videos as a great way to initiate new workers into following standards while still saving time.

5. The Fifth S – Shitsuke – Sustain

Continuous improvement must occur in the processes, procedures, and operations of the warehouse. Standardization is ineffective without sustenance.

How to Sustain:

- Encourage the staff to accept change, take improvement to a new level, and not return to old standards.

- This will pave your way to Kaizen, the principle that says change is good, and so things must always be improved.

- Conduct regular audits and checks to make sure that standards are followed.

- Incentivize high performances with a bonus and time off.

- Give consideration to creative and innovative ideas from employees.

- Be open to creating new standards if the present standards are not working out.

Companies have introduced a sixth S more recently – Safety, since it lies at the heart of warehouse operations.

6. The Sixth S* – Safety

The idea is to make warehouses safer for the workers, which also lets you avert litigation by preventing accidents.

How to Ensure Safety:

- Conduct warehouse safety risk assessment at regular intervals.

- Review warehouse layout and design with a view to safety, including factors such as walkways, ramps/stairs, racking, escape routes, etc., and make necessary changes.

- Have a fire and emergency plan that includes:

- Fire/emergency exits and evacuation procedures

- Location of fire extinguishers and emergency water hoses

- Tracking of all visitors and employees visiting the site at any given time.

As warehouse digitalization becomes more promising and traditional warehouses are disrupted, lean warehousing lends itself to a simple yet effective way to attain transformation and competitive advantage. It also means that you can tap technology to improve your lean warehouse, since digitization is also all about simplifying and making processes more efficient.

If you are ready to find the solution to optimize your warehouse, go to our Solutions Finder tool.

If you want more warehouse content or are curious about “Warehouse Digitalization,” you can follow us on LinkedIn, YouTube, X, or Facebook. You can also message us through our contact page if you have other inquiries. We’ll be happy to help.