Choosing the ideal warehouse location is pivotal for operational effectiveness, efficiency, and profitability. This decision, whether it’s leasing or purchasing a warehouse space, stands as a cornerstone in a company’s strategy to bolster competitiveness and serve its customers better.

The right location can drastically streamline operations, cut costs, and ensure timely delivery of goods, directly influencing customer satisfaction and the bottom line. In the quest for the perfect warehouse location, it’s essential to deliberate on various criteria meticulously.

Click Here: Efficiently Manage Your Warehouse With This Advanced and Affordable WMS

This article aims to guide you through seven critical factors to consider when scouting for a warehouse location. From analyzing rent rates and taxes to evaluating workforce availability and considering proximity to key transportation hubs, we’ll walk you through the essential steps to make an informed decision.

Before leaping into a commitment, it’s crucial to gather, compare, and analyze all relevant data to ensure your chosen location aligns with your business goals and logistics strategy. Let’s dive into the selection criteria to identify the best possible warehouse location for your operations.

Rent Rates & Taxes

Cost will remain a key criterion when selecting the right location for a warehouse, but it must not be the only one. Hidden costs could offset any savings on cheap rental rates and, therefore, must be considered.

The rental rate of a warehouse in the US is normally based on square feet (SF) per year or month, depending on the landlord. Average prices in the US can range from as low as $2.56 SF/Year and as high as $16.50 SF/Year. See the table below for the top 6 low & high-cost markets.

Data Source: Industrial Market Outlook 2017

In addition to rates, attention must also be given to local governmental regulations, tax structure, and tax incentives. You could also benefit from special local government programs to promote your industry segment, so it pays to consider this.

Workforce Availability, Labor Skills & Costs

Workforce availability, skills, and labor costs are directly associated with local demographics. Not every geographical location offers a workforce with the right skills at the right price. Pay attention to the local demographics of the state/city being considered.

When evaluating workforce availability, consider supply and demand: Low workforce availability and high demand will drive salaries up (meaning operating costs will be higher). The opposite is also true. High levels of workforce availability and low demand will drive salaries down.

Besides workforce availability and costs, skills are also critical. A workforce skill gap will result in a low quality of customer service and reduced competitiveness and productivity.

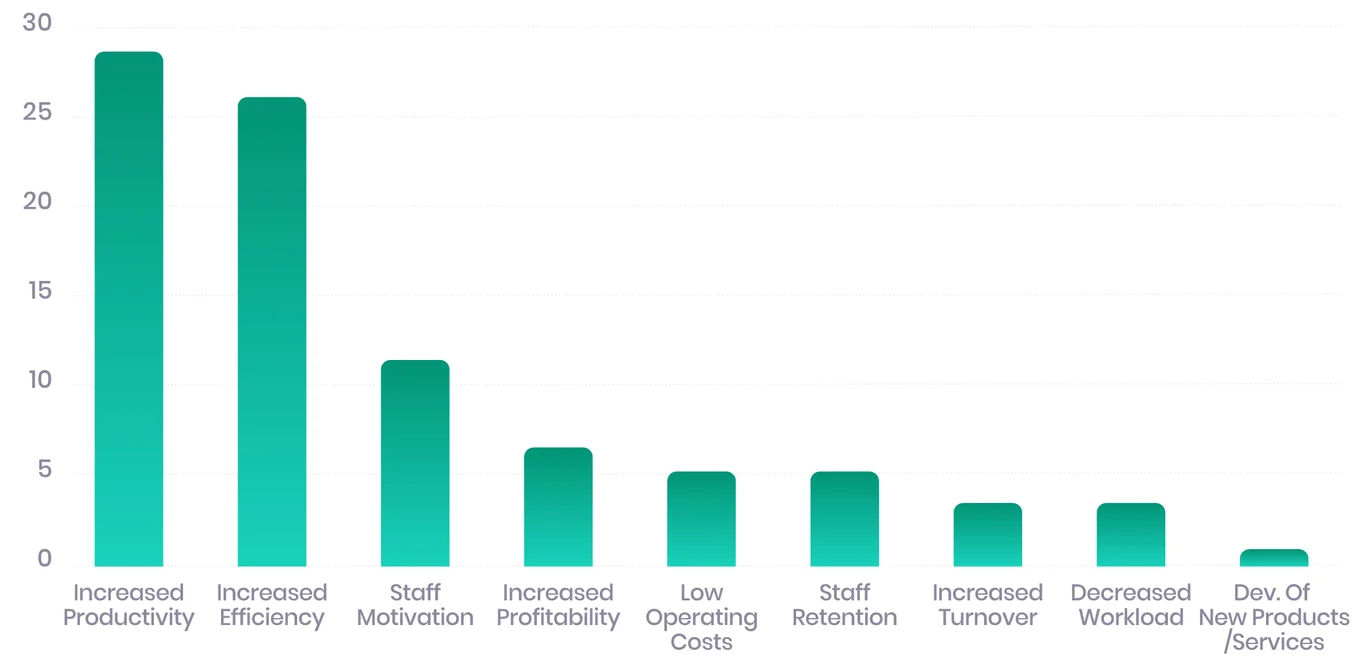

The following chart demonstrates the impact of a qualified/trained workforce in the logistics industry.

So, when choosing a warehouse location, research the demographics and focus on educational attainment, population characteristics & income levels. A quick Google search for “[city or state] demographics” should pull up the needed information. City and state government websites are also likely to provide this information.

Roads, Highways & Traffic Flow

Accessibility to roads and highways and local traffic density must also be considered, especially if trucking is the main mode of transportation.

Transportation costs are affected by some or all of these variables and can impact the competitiveness of the company or the attractiveness of the warehousing facility to customers. Consider the following points:

- Accessibility to highways & exit ramps

- Highway inter-connectivity

- Public transportation penetration

- Average traffic speed

- Average traffic volume

- Traffic peak hours

- Road safety & conditions

- Proper road signs & signals

Factors such as congested highways and surface roads and poor signaling systems will increase fuel consumption, accident rates, and time wasted.

Proximity to Airport, Railway Stations & Ports

In this case, the main mode(s) of transportation used to receive or ship goods to and from the warehouse must be prioritized. For example, if most cargo is imported/exported via air, you want to be as close as possible to the airport. If this is not possible, you should at least explore facilities with easy access to highways and roads directly connecting to the airport.

You want to be as close as possible to the point of the most predominant transportation mode to control drayage costs and have the highest possible velocity level – the maximum number of containers per month.

Markets & Local Environment Factors

Proximity to suppliers, producers, and the market(s) being served, as well as local environmental factors, must also be considered.

Any new warehouse should be close to major suppliers, producers, and/or customers. This will help reduce lead times, decrease transportation costs, and enhance responsiveness.

The factor to consider here is who is/are the major supply chain partner(s) and how to make the supply chain more efficient by strategically selecting the warehouse location.

Also, local environmental factors such as weather conditions and risk of exposure to natural disasters should be considered.

Would the warehouse be exposed to hurricanes, tornadoes, or earthquakes? Is it in a flood zone? For any of these risks, the warehouse must meet specific building requirements.

Other local environmental factors should also be considered, including proximity to neighbors (warehouses can be noisy – avoid disputes), traffic congestion, and peak traffic hours. Consider how these variables could affect regular operations.

Building Availability & Utility Costs

If the business grows or shrinks, you will need to adjust accordingly. If this is the case, you will want to minimize your need to re-evaluate all these factors if moving to a new warehouse is your only option. By moving within the same area, you will be able to retain your workforce, utilities, etc., and minimize the frustrations of carriers/truckers and customers trying to find the new location.

One last aspect: utilities. You will want to double-check the availability and cost of utilities. Some warehouses are more demanding/dependent on one utility than another. For example, refrigerated warehouses are more dependent on electricity and water.

But there is one utility that almost everyone ignores: the internet and communication services. Remember to check not only the availability of internet services but also the speed and link type (Cable, T1, Fiber, etc.) available and all associated costs. Also, remember that on occasion, the installation of internet services can take up to 3 months – or more.

Summary

Please take the time to plan and understand the most strategic warehouse location for you and your customers properly. The impact of this decision is much more significant than just opening a warehouse somewhere. The location of your warehouse will have long-lasting effects on the financial, operational, and competitive aspects of the company.

Now that you have understood the importance of choosing the right warehouse location, it’s time to consider the principles of warehouse layout design. This will help you properly utilize space, facilitate smooth operations, and increase efficiency.

If you want more warehouse content, you can follow us onLinkedIn, YouTube, X, or Facebook. You can also message us through our contact page if you have other inquiries.