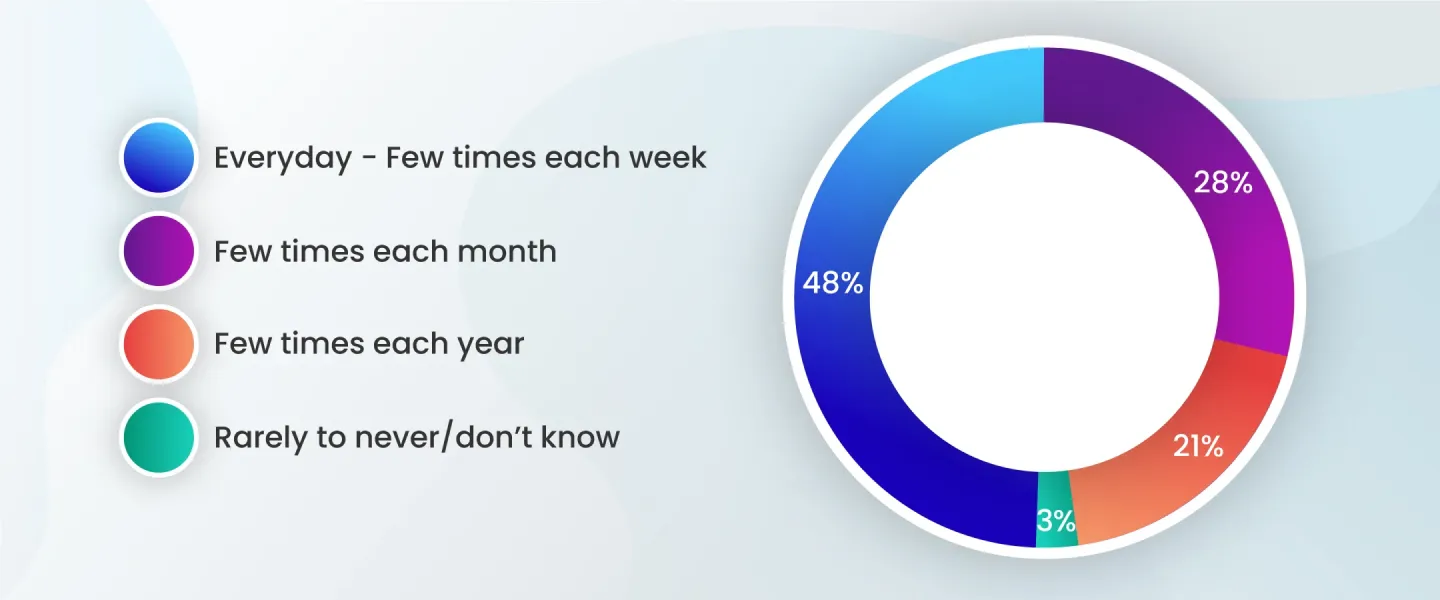

Warehouse technology issues too often bring businesses to a halt. In a study by Compuware, almost half of the respondents (48%) reported that technology problems happen anywhere from a few times a week to every day. Seventy-five percent reported that the frequency of technology failures is staying the same or increasing.

Click Here: Boost Your Warehouse Efficiency With This Advanced and Affordable WMS

How often does your company experience information technology issues that affect performance or productivity in your area (excluding website failures)?

More often than not, the problem goes beyond what meets the eye. A technology issue usually has an underlying cause that could easily have been avoided.

Over the last two years, we have provided warehouse tech support for over 266 businesses and collected data from 10,451 technology support requests received.

In this article, we’ll highlight the five most common warehouse IT problems impacting small- and mid-size companies.

1. Warehouse Wireless Instability & Handheld Disconnections

Poor warehouse wireless coverage, network instability, and random handheld disconnections are at the top of the list. Around 87% of the companies we have worked with experienced one of these problems.

Most Common Causes of Wireless Instability & Handheld Disconnections:

- Badly planned wireless warehouse implementation: Very often, wireless networks are installed by companies that are not warehouse systems integrators, and they are unfamiliar with the particular challenges of implementing a warehouse wireless solution. This often causes the network to malfunction because it does not meet the needs of the warehouse.

- Selecting the wrong wireless solution: Driven by the desire to reduce costs, companies very often select wireless solutions that are not intended for warehouse environments, handheld devices that are not compatible, or second-hand equipment that is often ineffective.

- Lack of equipment standardization and configuration: Non-standardization between a hardware vendor and a device model will create major headaches and a painful troubleshooting process when things go wrong. Standardization among a vendor, device models, and system configurations will help to avoid issues.

2. Printing & Scanning Issues

Warehouses need to print shipping labels and scan documents quickly. The inability to do so can cause productivity lags and other problems along the supply chain.

For the most part, printing and scanning-related issues include: users not being able to print/scan due to connectivity issues, printer alignment problems, not knowing how to identify the proper printer in the network, printers not available in the WMS/TMS systems, scanned documents taking too long, and driver incompatibilities.

Most Common Causes of Printing & Scanning Issues:

- Lack of proper planning: Many organizations fail to plan (or hire someone to plan) the deployment and management of their printing and scanning infrastructure in a way that is reliable and simple to manage.

- Lack of printer/scanner standardization: You should have printer/scanner standardization across vendor, model, deployment method, naming convention, and printing software (drivers). For example, if all of your label printers are from Zebra (vendor) and use model GK420, this is the vendor and model standard. You should install that printer driver on a server and deploy it to all the computers from there. Use a naming convention identifying your business structure (city, department, unit number: MIA-WH-1).

- Decentralized management of printing infrastructure: You should standardize and centralize the management of the printing infrastructure as much as possible. For example, install all printer drivers on one server and manage all the printers from there. This reduces complexities and administration overhead.

3. WMS TMS Problems

At the core of most supply chain businesses, two systems play a critical role: Warehouse Management Systems (WMS) and/or Transportation Management Systems (TMS).

The critical role of WMS & TMS is often underestimated by decision-makers when selecting the right TMS/WMS solution for their company.

Most Common Causes of WMS/TMS Problems:

- System instability: Most software has services—a subset of applications within the software that perform specific functions for the program. Recurrent service failures cause system instability, especially if the service(s) plays a critical role within the application. This is a very common problem across many WMS and TMS systems.

- Improper software updates: Companies tend to introduce new software updates before properly testing them, which creates unplanned downtime.

- Poor quality database systems: Before buying a WMS or TMS, businesses might fail to evaluate them against business needs and future growth. As the business and the data stored in the WMS or TMS grows, system performance degrades because databases are not properly designed for scalability.

4. IT Infrastructure Problems

Your technology infrastructure comprises computers, network devices, servers, and software. It is the technical core of your business—the central component that interconnects people and data. This is where information, including sales quotes, emails, bills of lading, and more, is processed and shared.

Very often, this core component of the business is undervalued, resulting in system problems that impact business productivity and create customer dissatisfaction.

The most common infrastructure issues across businesses include slow network speeds, random network disconnections, computer and server performance degradation, security breaches, and unreliable equipment or software.

Most Common Causes of IT Infrastructure Problems:

- Poorly architected infrastructure and incorrect implementation, causing desktops, networks, and servers to fail.

- No standardization of hardware and software solutions.

- Lack of basic security, not just for technology systems but also in operations.

- Technology underinvestment is driven by the desire to reduce costs. This becomes counterintuitive because it increases costs due to operational deficiencies or the need to re-install the solution to get things working right (e.g., implementing home technology solutions instead of business solutions).

5. Lack of Technology Management

Last but not least is technology management. This is one area where we see many deficiencies originating.

There’s a misconception amongst decision makers that technology can be implemented without being managed or hiring remotely managed IT services. Well, I’m here to tell you this is not the case—especially if you expect things to run smoothly.

Like everything else in your business, technology needs to be properly maintained. Failing to properly and proactively manage technology exposes the business to technology failures and security breaches.

Most Common Symptoms of Poor Technology Management:

- Unscheduled downtimes force businesses to come to a halt. I call this “technology managing the company”—not the company managing technology, which is the way it should be.

- Lack of system monitoring to detect deficiencies and problems before they occur.

- There is a lack of proactive maintenance plans to keep systems up to date with the latest security and software updates to correct software and system bugs.

- No historic I.T. operational data to make informed technology investment decisions and detect operational deviations.

“According to Compuware’s study, 52% of responders classified supply chain operations as critically dependent on technology operating effectively, 43% consider it critical in distribution departments, and 39% in shipping & receiving.”

Source: The True Cost of Poor Technology Performance

Technology is a living, breathing organism and a crucial part of any supply chain business. IT decisions need to be made after considering what is right for your business. Then technology infrastructure needs to be implemented and managed properly, so security breaches, unscheduled downtime, and all the other issues we discussed today do not happen to your business.

If you want more warehouse content or are curious about “Warehouse Digitalization,” you can follow us on LinkedIn, YouTube, X, or Facebook. You can also message us through our contact page if you have other inquiries. We’ll be happy to help.