Warehouse technologies can directly impact one of the most critical strategic goals and differentiators for logistics organizations: warehouse efficiency. If warehouse operations run inefficiently, the business must increase its workforce to maintain high service levels.

However, adding additional employees often results in the erosion of profit margins and a warehouse operation that is more prone to human error. To meet this challenge, many warehouses are looking to technology for solutions that automate repetitive tasks and reduce errors.

Click Here: Boost Your Warehouse Efficiency With This Advanced and Affordable WMS

Other organizations are analyzing every warehouse process and removing unnecessary steps – even eliminating some processes altogether.

The most successful businesses are doing both.

By eliminating unnecessary processes and implementing error-reducing technologies, businesses increase warehouse efficiency and profitability while better positioning themselves to compete in an already highly competitive industry.

In this article, we explore three technologies aimed at increasing warehouse efficiency.

3 Technologies to Improve Warehouse Efficiency

1. Dimensioning Systems

Pallet and box dimensioning can be very time-consuming. We’ve noticed that, on average, it can take a receiving clerk between 40 and 55 seconds to manually measure cargo dimensions and enter them in the WMS. All this without considering the likelihood of error when done manually.

A key technology that warehouse managers and decision-makers must consider when looking to increase warehouse efficiency is dimensioning systems.

Pallet and parcel dimensioning systems are extremely effective at automating the measurement and verification steps involved in the receiving process.

“Warehouses that have implemented dimensioning systems reduced the time spent measuring boxes and/or pallets by at least 68%.”

Dimensioning systems measure pallets and/or boxes, putting the dimensions automatically into the warehouse receipt. Some can even be integrated with the scale to allow you to capture dimensions and weight automatically into the receipt.

Additionally, some dimensioning systems go so far as to capture high-definition digital snapshots of the cargo to allow customers to see the state of their shipment – all in less than 10 seconds. See the image below of a pallet dimensioning system in action.

In addition to increasing warehouse efficiency, dimensioning systems reduce data entry and collection errors. NTEP-certified and commercial-grade dimensioning systems (no Kinect driven devices) have a reliable accuracy of ±0.25″/ ±0.50″. When these warehouse technologies are integrated with the warehouse management system (directly or indirectly), data entry errors become a thing of the past.

2. Mobile Technology

In most warehouses, the average clerk makes 30+ trips a day back and forth from a fixed station to print picking lists and labels or to enter shipment data into a computer.

Mobile warehouse technology gives workers immediate access to systems anywhere in the warehouse.

Still today, most warehouses continue to use fixed stations to perform basic data entry or to print picking lists and labels. Warehouses that do so are inherently inefficient.

Some mobile technologies that increase warehouse efficiency include portable computers, mobile printers, and wearable barcode scanners.

a. Mobile Computers

Robust computing power is no longer confined to desktop computers and servers. Warehouses can now find the same reliability, computing power, and standard business applications in warehouse technologies such as mobile computers and rugged tablets.

Most rugged tablets and mobile computers have been designed to withstand extreme warehouse conditions (temperature, humidity, dust, shock, etc.). Many have military-grade certification (MIL-STD 810G ruggedness), so you don’t have to worry about durability. They are also equipped with long-lasting batteries and reliable wireless network capabilities.

b. Mobile Printers

Mobile printers allow workers to generate labels from anywhere in the warehouse. From the receiving gate to the bay or the loading area, so long as there is a good wireless warehouse network, clerks can print labels on-site and reduce walking time.

c. Wearable Mobile Computers & Barcode Scanners

These warehouse technologies are necessary for organizations striving to modernize their operations and increase warehouse efficiency.

Barcode scanners are at the center of an efficient warehouse. From receiving to put-away to picking, packing, sorting, and shipping, barcode scanners are no longer a nice-to-have – but a must-have.

The old barcode scanner is evolving into a more mobile, ergonomic, and friendlier device: the handheld scanner/computer. Warehouse technologies such as the wearable ring barcode scanner provide a hands-free benefit that allows warehouse workers to remain productive and mobile without compromising between picking cargo and holding the scanner.

To learn more about how mobile warehouse technology works and what are its corresponding benefits, watch the video below: https://youtu.be/s6LI-oh7RbY.

3. Best-of-Breed WMS

We’ve discussed all the technological revolutions happening in the warehouse and how these solutions can create more efficient warehouse operations. However, the reality is that without a warehouse management system that can leverage these technologies, there is not much that one can do about warehouse efficiency.

Best-of-breed warehouse management systems provide this level of functionality or at least an easy way to integrate with these warehouse technologies.

So, what are the three most important characteristics of a WMS that allow a business to benefit from technological advances that improve warehouse efficiency?

It must be mobile-friendly, easy to integrate, and process-oriented, among others. Let’s discuss this a bit more.

a. Mobile Friendly

A mobile-friendly warehouse management system allows warehouse employees to work across a platform of mobile warehouse technologies, from smartphones to tablets. This is normally accomplished via a native mobile application (a smartphone application) or a responsive web application (web-based software that adjusts to the screen size of the device or browser the user is operating).

b. Easy, Low-Cost Integration

No system has it all, and the ability to easily and cost-effectively integrate with other systems is one of the main characteristics that make best-of-breed WMSs so special.

Look for a system that can easily integrate with other systems and warehouse technologies. And make sure the WMS provides a reliable and well-documented API (application programming interface). Evaluate the costs associated with using the API. Some vendors follow the Salesforce model (API usage is based on license edition), others charge a reasonable monthly fee, and some charge per transaction. The latter is the least favorable because it’s unpredictable and hard to budget.

c. Workflow & Process Oriented

In an industry where the flow of goods needs to happen fast and without errors, it’s a challenge to keep things running smoothly when many small and mid-sized warehouses experience high workforce turnover rates.

Because of this, it is important that the WMS offer a way to define and enforce warehouse processes through workflow engines as well as a way to measure the efficiency of such processes and the productivity of employees – features often found in best-of-breed warehouse management systems.

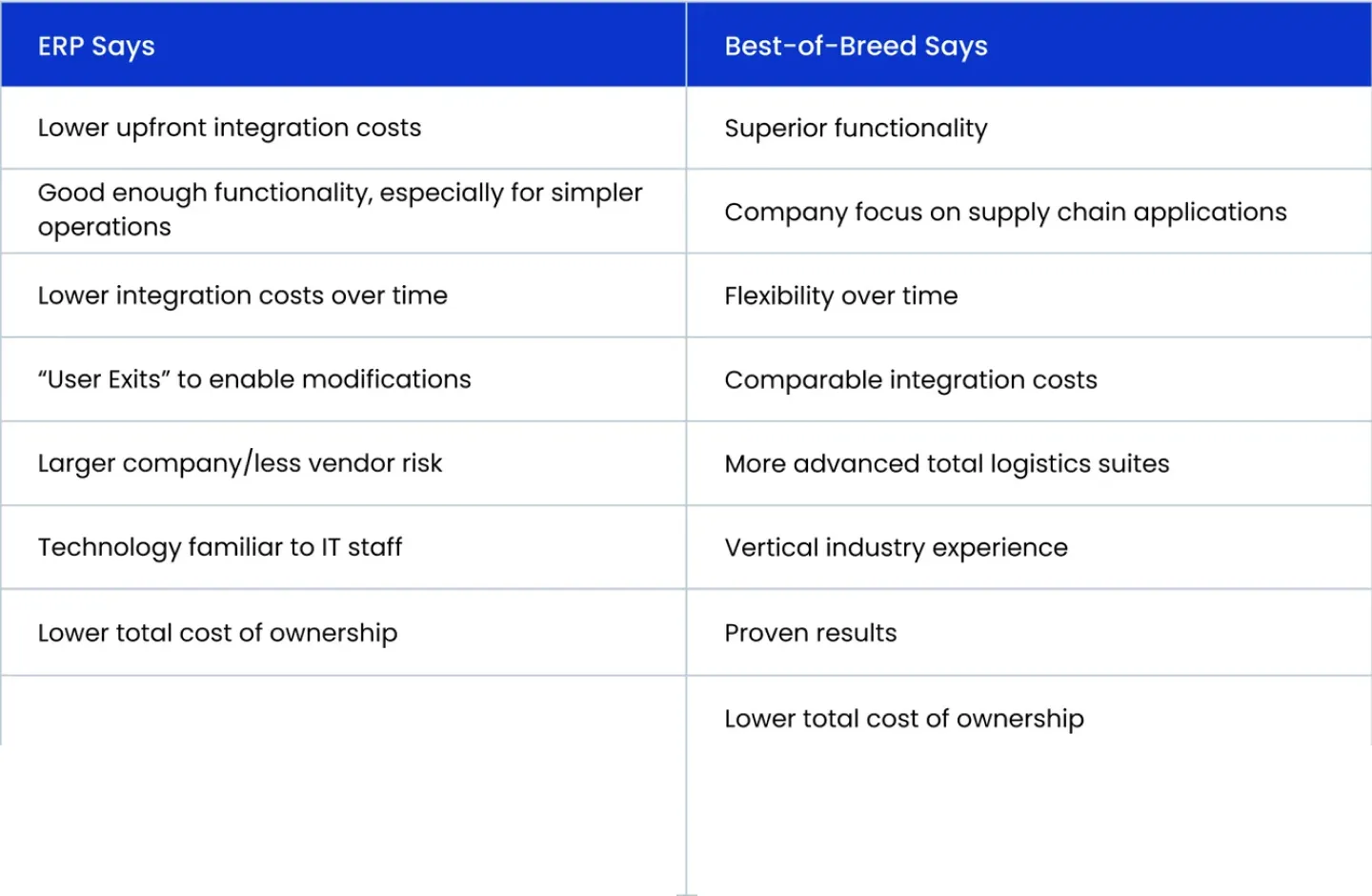

Every business would love to be able to afford an ERP, but ERP costs are prohibitive for small/mid-sized logistics companies. The good news is that a best-of-breed WMS can come very close to an ERP without breaking the budget.

Source: Supply Chain Digest

New warehouse technologies have opened a door of opportunity for warehouses to become more efficient and businesses more competitive.

In the coming years, companies willing to embrace new warehouse technologies (and successfully implement them) will be positioned to remain competitive and profitable.

The rapid evolution of technology will continue to accelerate—just as Gordon Moore observed in 1965 (Moore’s Law). Companies that don’t evolve are at risk of falling behind, or worse, falling off the train completely.

If you are ready to evolve and improve your warehouse efficiency using technologies, go to our Solutions Finder tool.

If you want to learn more about warehouse digitalization and optimizing warehouse processes, you can follow us on LinkedIn, YouTube, X, or Facebook. If you have other inquiries or suggestions, please contact us here. We’ll be happy to hear from you.